28+

Years of experience

- About capcover

CAPCOVER PRESENTATION

CAPCOVER is a company that provides EPE and aluminum seals for induction sealing of containers in the food, cosmetic, pharmaceutical, and chemical industries.

The company has the technology, experience, and expertise to provide the best solution for the products of each packaging company. CAPCOVER offers a comprehensive service to achieve the best sealing for its products: full product analysis, design of the appropriate solution, and progressive die-cutting.

- Experienced workers

- Take care of customer satisfaction

- Stable partner on a global scale

- capcover

Our values

At CAPCOVER, we are guided by core values that shape our approach and relationships with our customers, partners and collaborators. These values are at the heart of our commitment to providing high-quality sealing solutions and building customer trust.

Innovation

We continuously invest in research and development to offer innovative sealing solutions tailored to the specific challenges of each sector.

Quality

We ensure products that meet the strictest standards, with exceptional reliability and performance at every stage of production.

- capcover

Sectors Activities

Pharmacy

Pharmacy

The pharmaceutical industry is characterized by the need for comprehensive quality control and the obligation to ensure the safety and efficacy of all medicines made available to the public. For pharmacy, packaging, conditioning, and sealing of pharmaceutical products are essential to guarantee optimal quality conditions, proper preservation, and certainty of sterility.

Beauty products

Beauty products

The cosmetics and fragrance industry requires highly demanding packaging to ensure the content's seal and to guarantee that the product's properties are not lost. In particular, companies in this sector need to protect the shades of makeup or to bottle the very specific and characteristic scent of their perfumes.

The world of aesthetics and beauty, with its endless possibilities for customization and exclusivity in containers, jars, bottles, and pots, requires bottlers and manufacturers of caps and sealing gaskets to adapt to their specificities and comply with safety standards. Sealing all your products. To achieve this, each container requires a different lid that meets its particular needs.

Alimantation

Alimantation

Food chains

Spices

Sauces.

Beverages.

Solubles.

Snacks.

Sweets.

Dried fruits.

Canned goods.

Etc.

Cleaning

Cleaning

Cleaning products are used to remove dirt from certain surfaces, depending on the composition and texture of the surface to be cleaned. Cleaning in an enclosed space is not the same as cleaning outdoors, just like cleaning one type of dirt or another that is embedded.

The properties of cleaning products could be harmless. However, cleaning containers usually contain substances that are corrosive for better efficiency, irritating to our skin or eyes, sensitizing if accidentally inhaled, harmful on direct contact or even toxic if safety and care precautions are not taken.

To avoid unnecessary risks, to handle cleaning product packaging with care and to ensure that it does not cause any harm, small or large, to users, it is essential to use seals and lids accompanying the caps, which ensure the hermetic and secure closure of the container.

Agrochemicals

Agrochemicals

Agrochemical bottling companies.

Fertilizers.

Fertilizers.

Pesticides.

Insecticides.

Etc.

Our Founder’s Vision

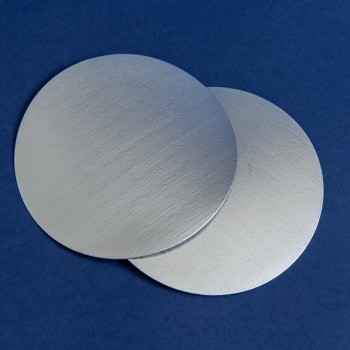

Induction Sealing 2-Piece

Two-Piece Separable Seal Prepared for Induction Sealing.

These sealing seals are made of a laminated film with aluminum, providing the closure with a tamper-evident seal for first use. It also prevents potential product leakage, maintaining its integrity and preventing any leaks. This special layer is initially bonded to a secondary sealing gasket, which ensures the airtight sealing of the container after its first opening.

One-Piece Security Seal

One-Piece Seal Prepared for Induction Sealing.

The material is composed of a polymer film made of polyethylene terephthalate (PET), expanded polyethylene (EPE), aluminum, and an additional sheet that acts as a seal. The acronym PET also refers to polyethylene terephthalate, polyethyleneterephthalate, or polyester. The acronym EPE also refers to polyethylene foam.

These sealing gaskets are the perfect closure seals to provide the packaged product with a tamper-evident seal for first use. Furthermore, they also ensure that there are no leaks of the product or any potential aromas before its first opening.

EPECOVER Hermetic Seal

Closed-cell foam sealing gasket, made of low-density polyethylene (LDPE), with or without a film on both sides of its surface.

It is distinguished by its high level of resistance and elasticity, as well as its excellent recovery capacity. Ideal for ensuring an airtight closure for all types of containers, bottles, or packaging. It does not allow any liquid or air to pass through.

These gaskets are typically the most commonly used closure seals for caps in the food, pharmaceutical, cosmetic industries, and, in general, for handling all types of chemical products.

There are various densities and thicknesses available. We also adapt to any diameter required, both in disc and washer forms.

- BLOG & NEWS