Introduction

Induction sealing is a crucial technology in many sectors, ensuring the airtightness and tamper-evidence of products. This solution guarantees the quality and safety of products while meeting the strict requirements of the food, cosmetics, pharmaceuticals, and chemicals industries.

How induction sealing works

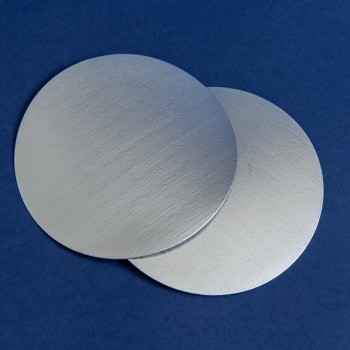

The induction sealing process is based on a simple yet effective principle. A sealer generates an electromagnetic field that heats a layer of aluminum in the seal. This heat melts a layer of polymer, which firmly bonds to the container opening, ensuring an airtight and tamper-evident seal.

Benefits for different sectors

- Pharmaceutical Industry: Guarantee of sterility and protection against contamination.

- Cosmetics: Preservation of aromas and product properties.

- Food: Prevention of leaks and preservation of flavors.

- Chemicals: Increased safety for potentially hazardous substances.

An environmental benefit

By preventing leaks and extending shelf life, induction sealing helps reduce food waste and the need for secondary packaging, thereby supporting a more sustainable approach.

Conclusion

CAPCOVER offers induction sealing solutions tailored to each client's needs. By combining advanced technology and customization, we help improve product safety and quality across various industries.